Description

Top Quality Hydraulic Accumulators|Enhance System Efficiency & Reliability

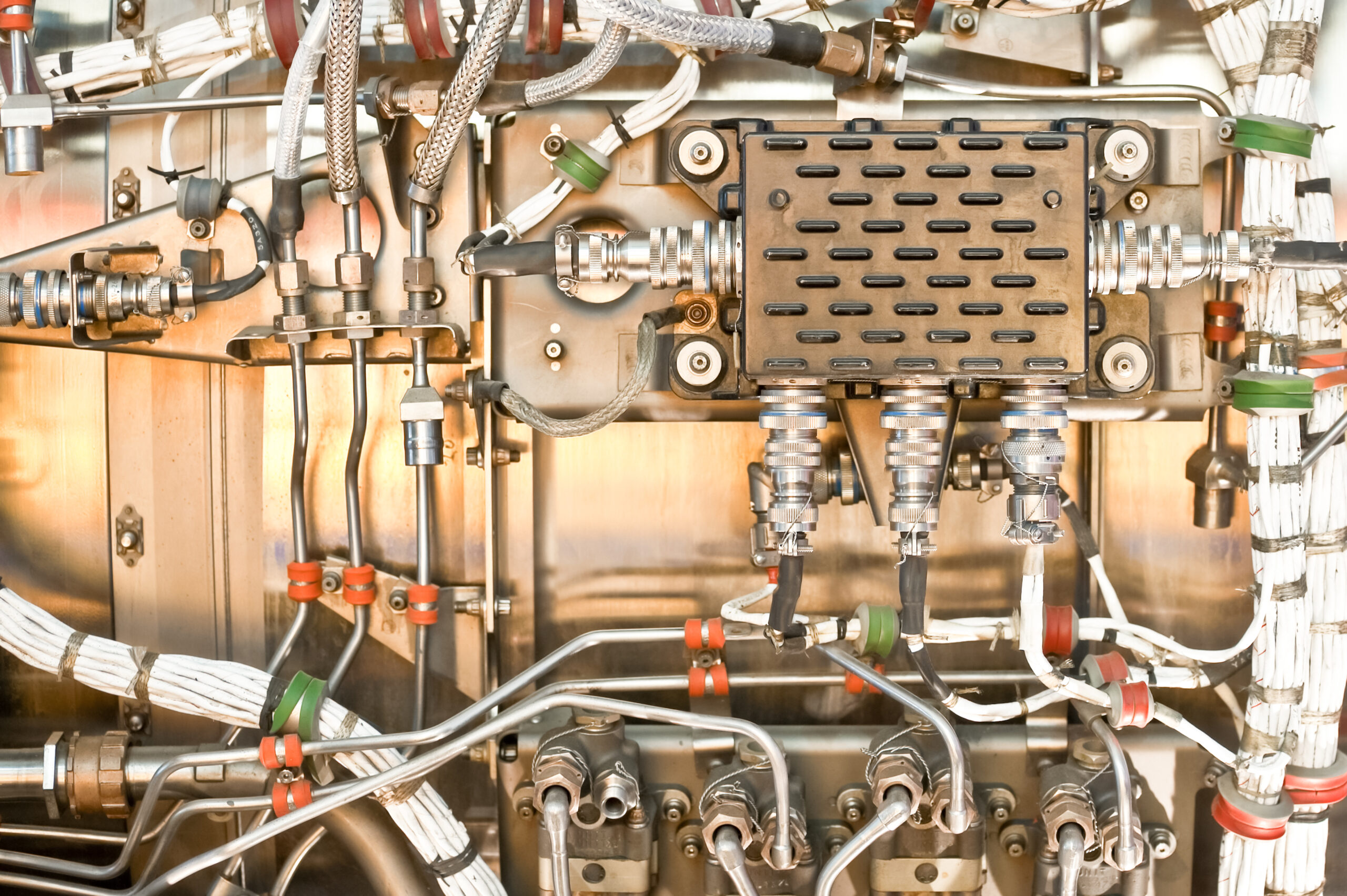

Hydraulic accumulators are essential components in various industrial and aerospace applications, providing reliable shock absorption and energy storage capabilities. At Aero Parts Global, we offer a wide range of high-quality hydraulic accumulators designed to meet the demanding requirements of our customers.

What are Hydraulic Accumulators?

Hydraulic accumulators are devices that store hydraulic energy in the form of pressurized fluid. They play a crucial role in hydraulic systems by absorbing shocks, maintaining pressure, and providing additional fluid when required. This functionality makes them indispensable in applications where consistent performance and reliability are paramount.

Key Features of Our Hydraulic Accumulators

- Robust Construction: Our hydraulic accumulators are built to withstand extreme conditions, ensuring durability and reliability in the most demanding environments.

- Customizable Designs: We offer a variety of designs and sizes to meet specific application requirements, ensuring you get the right accumulator hydraulic solution for your needs.

- Compatibility: Our accumulators are compatible with various hydraulic fluids and can operate under a wide range of temperatures and pressures.

- Efficient Shock Absorption: Designed to minimize pressure spikes and fluctuations, our hydraulic accumulators enhance the stability and performance of your hydraulic systems.

- Industry Compliance: All our products comply with industry standards and regulations, ensuring safety and reliability.

Benefits of Using Hydraulic Accumulators

- Improved System Efficiency: Hydraulic accumulators help maintain system pressure, reducing the workload on the hydraulic pump and improving overall efficiency. This leads to lower energy costs and extended equipment life.

- Enhanced Safety: By absorbing shock loads and pressure spikes, hydraulic accumulators protect sensitive components and prevent system failures, ensuring the safety of both personnel and equipment.

- Increased Energy Savings: Accumulators store energy during periods of low demand and release it when needed, optimizing energy consumption in hydraulic systems.

- Reduced Maintenance Costs: By minimizing pressure fluctuations and shock loads, hydraulic accumulators help extend the lifespan of system components, reducing the frequency and cost of maintenance.

- Versatile Applications: Our hydraulic accumulators are suitable for a wide range of applications, including aerospace systems, hydraulic power units, industrial machinery, mobile equipment, and oil and gas operations.

Why Choose Aero Parts Global for Your Hydraulic Accumulators?

At Aero Parts Global, we are committed to providing our customers with the highest quality hydraulic accumulators and exceptional customer service. Our team of experts is ready to assist you in selecting the right accumulator hydraulic solution tailored to your specific needs.

- Expert Guidance: Our knowledgeable staff can help you navigate our extensive catalog to find the perfect hydraulic accumulator for your application.

- Competitive Pricing: We offer competitive pricing without compromising on quality, ensuring you receive the best value for your investment.

- Fast Shipping: We understand the importance of timely delivery, and we strive to ship your orders quickly to minimize downtime.

- Customer Satisfaction: Our commitment to customer satisfaction means we are always here to support you, whether you have questions about our products or need assistance with your order.

Explore Our Selection Today!

Browse our selection of hydraulic accumulators at Aero Parts Global and discover how our products can enhance the performance and reliability of your hydraulic systems. Contact us today to learn more about our offerings and how we can help you find the perfect solution for your application.

Elevate your hydraulic systems with our premium hydraulic accumulators—where quality meets performance!

What are hydraulic accumulators?

Hydraulic accumulators are pressure vessels that store energy in the form of pressurized fluid. They are used in hydraulic systems to maintain pressure, absorb shock, and smooth out pulsations.

What does an accumulator do in a hydraulic system?

Hydraulic accumulators perform several key functions in a hydraulic system:

- Store energy during periods of low demand and release it when needed, improving system efficiency

- Absorb shock loads and pressure spikes, protecting sensitive components and preventing system failures

- Maintain system pressure, reducing the workload on the hydraulic pump

- Dampen vibrations and pulsations, ensuring smooth and stable operation

What are the main types of accumulators used in hydraulic systems?

The three most common types of accumulators used in hydraulic systems are:

- Bladder accumulators: Consist of a fluid chamber separated from a gas chamber by a flexible bladder. Offer fast response times and good dirt tolerance.

- Piston accumulators: Use a piston to separate the fluid and gas chambers. Can handle higher gas compression ratios and flow rates than bladder accumulators.

- Diaphragm accumulators: Similar to bladder accumulators but use a diaphragm instead of a bladder. Can withstand higher gas compression ratios than bladder accumulators.

How does a hydraulic accumulator work?

Hydraulic accumulators work by storing energy in the form of pressurized fluid. When the pressure in the hydraulic system rises, fluid enters the accumulator and compresses the gas (usually nitrogen) in the gas chamber. When the pressure drops, the compressed gas expands and forces the fluid back into the hydraulic circuit.

What factors should be considered when selecting a hydraulic accumulator?

Several factors must be considered when choosing a hydraulic accumulator for a specific application:

- Energy storage capacity required

- Type of accumulator (bladder, piston, diaphragm)

- Operating pressure and temperature range

- Compatibility with the hydraulic fluid

- Size and weight constraints

- Installation and maintenance requirements

- Environmental factors such as temperature and humidity

What are the benefits of using hydraulic accumulators?

The main benefits of using hydraulic accumulators include:

- Improved system efficiency and energy savings

- Enhanced safety by absorbing shock loads and pressure spikes

- Extended lifespan of hydraulic components due to reduced wear

- Lower maintenance costs and downtime

- Versatility in a wide range of industrial and aerospace applications

How do you maintain a hydraulic accumulator?

Proper maintenance of hydraulic accumulators is crucial for ensuring reliable operation and long service life. Key maintenance tasks include:

- Regularly checking and maintaining the correct gas pre-charge pressure

- Inspecting for external damage or leaks

- Performing periodic testing and certification as required by local regulations

- Replacing worn or damaged components, such as seals and bladders, as needed

Remember, hydraulic accumulators are pressure vessels and must be treated with the appropriate safety precautions. Always follow the manufacturer’s recommendations and local safety regulations when working with accumulators.

Reviews

There are no reviews yet.